|

|

| |

|

| |

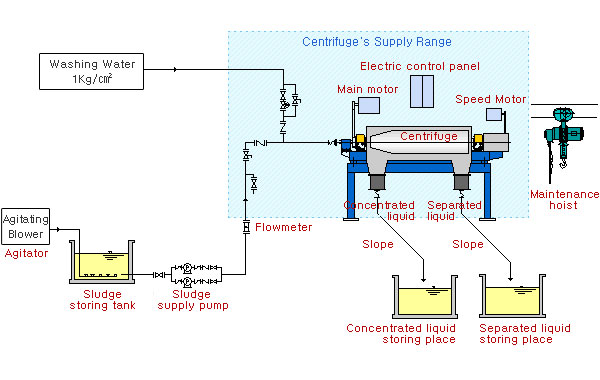

* Click on the image to see a larger image |

|

|

|

|

| |

|

| Unlike traditional decanter centrifuges, this centrifuge boasts less environmental damage, easier running with full automatic operation, more than 90% solid removal of low Thickening surplus sludges without coagulant and more removal with small coagulant, 1%-10% adjustable Thickening of discharged solid, automatic screw speed control depending on the change in sludge Thickening, and speed sensor adjusting function for continuously consistent discharge of concentrate. |

| |

|

| - Surplus or initial mixed sludges resulting from waterworks, sewage, cattle excrements and wastewater disposal facilities

- Coagulant-feeding model is suitable when solid recovery is not good due to lower sludge settling and increase in treating capacity. |

| |

|

| |

|

|

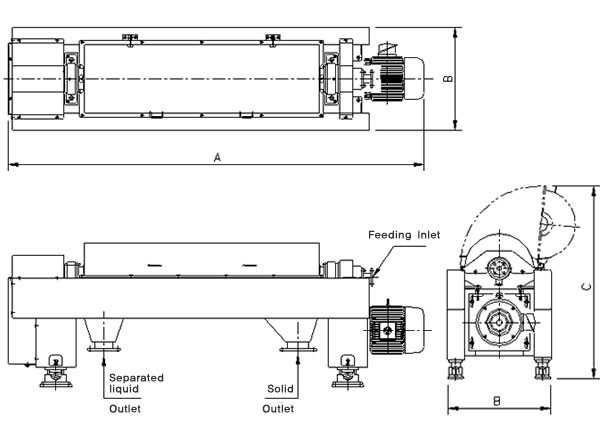

| Model |

Treating

Capacity (㎥/hr) |

Main power motor (kw) |

Centrifugal

Force(G) |

Weight (kg) |

Dimension (mm) |

| A |

B |

C |

| MCL-200C |

1~5 |

5.5~7.5 / 1.5~2.2 |

2000~3000 |

800 |

2370 |

650 |

1200 |

| MCL-300C |

5~10 |

11~22 / 3.7~5.5 |

“ |

2000 |

3260 |

780 |

1440 |

| MCL-400C |

10~20 |

30~37 / 5.5~7.5 |

" |

3000 |

3720 |

910 |

1690 |

| MCL-500C |

20~30 |

37~45 / 7.5~11 |

“ |

4000 |

4075 |

1100 |

1890 |

| MCL-600C |

30~50 |

45~55 / 11~15 |

“ |

5000 |

5000 |

1200 |

1950 |

| MCL-700C |

50~70 |

55~75 / 11~15 |

“ |

6500 |

6000 |

1300 |

2100 |

|

| Notes) |

1. The above treating capacity is based on 0.8% surplus sludge without coagulant. When the coagulant is added, therefore, there must be 30%-50% increase in the treating capacity, according to the type of sludges. The electric rate, special material and initial tile are optional.

2. The above specifications are subject to change without prior notice for the quality enhancement. |

|

| |

|

|

|

| |

|